CIRCULATING PUMP

When you choose JMI Mechanical, you’re getting skilled and friendly technicians with a trustworthy brand and reputation. We take pride in our work because we genuinely enjoy what we do, and it reflects in our service!

What is a Circulating Pump, and How Does It Work?

Circulating pumps are essential components in various systems, facilitating the movement of fluids within closed loops. They play a crucial role in circulating liquids, such as water or coolant, through pipes, ensuring consistent flow and temperature regulation. Understanding the functionality and significance of circulating pumps is fundamental for optimizing system performance and efficiency.

Types of Circulating Pumps

Circulating pumps are like the engines that keep fluids moving in various systems. There are different kinds, each made for specific jobs and needs. Let’s take a closer look at three main types: centrifugal pumps, recirculating pumps, and submersible pumps.

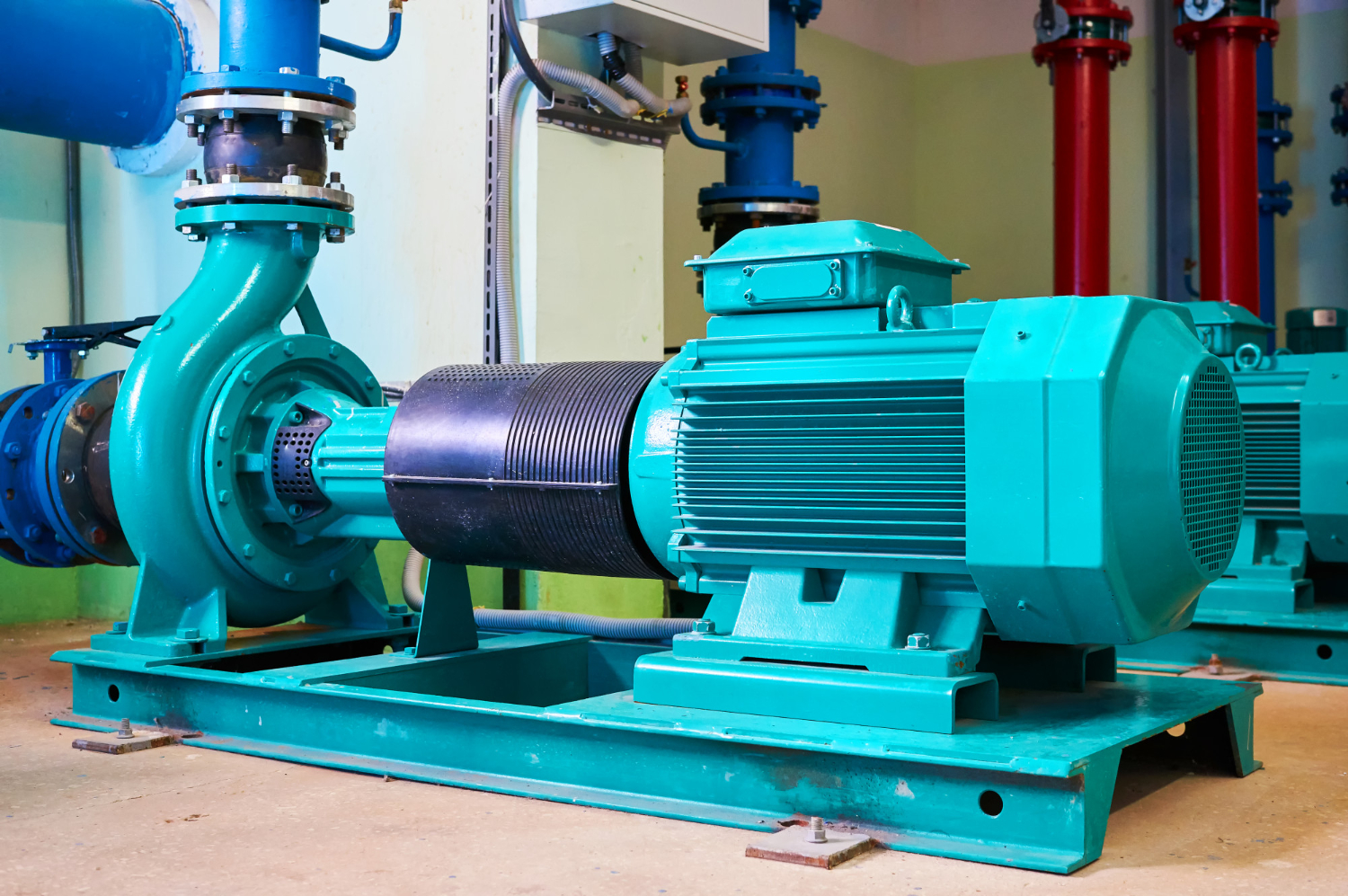

Centrifugal Pumps:

Think of centrifugal pumps as the sprinters of the pump world. They use a spinning motion to push fluids forward with speed. You can find them in heating, cooling, and ventilation systems, like those in buildings or factories. They’re also handy in industrial processes where fluids need to keep moving without stopping.

Recirculating Pumps:

Recirculating pumps are like the circulatory system of a closed loop. They’re all about keeping fluids moving continuously within a set path. These pumps are great for systems that need to maintain a steady flow and temperature, like hot water systems. By keeping the water in motion, they make sure you get hot water fast from your faucet without wasting energy.

Submersible Pumps:

Imagine a pump diving underwater to do its job—that’s a submersible pump. These pumps get right into the fluid they’re moving, often placed in wells or pits. They’re strong enough to handle liquids with lots of solid stuff in them. You’ll find them hard at work in places like sewage treatment plants, where they help drain out waste, or in farms, where they assist in watering crops.

How Circulating Pump Work

Imagine a circulating pump as a powerful helper that moves liquids around in a system. It’s like when you use a straw to drink a milkshake – you suck on one end, and the milkshake moves up through the straw and into your mouth.

Now, instead of a straw and a milkshake, picture a pump with an impeller inside. The impeller is like a fan or a propeller. When the pump is turned on, the impeller starts spinning really fast. This spinning creates a force that pushes the liquid away from the center of the pump and out into the pipes of the system button and temperature control within the system.

Applications of Circulating Pump

Circulating pumps are like the engines that keep things moving smoothly in many industries. They’re used for heating, cooling, and managing liquids in different processes. Here’s where you might find them in action:

Heating Systems: In buildings, circulating pumps help to push hot water or steam through systems that warm up the indoor spaces. So, when you feel cozy on a cold day thanks to the radiators or underfloor heating, it’s likely because of these pumps.

Cooling Systems: Ever wonder how refrigerators and air conditioners work? Well, circulating pumps play a key role here too. They help to circulate fluids that absorb heat, keeping your fridge chilly or your room cool.

Domestic Water Supply: In homes and offices, circulating pumps make sure water flows smoothly through pipes and faucets. This not only ensures you have water whenever you need it but also keeps the water pressure steady, making showers and washing dishes more convenient.

Industrial Processes: Factories and power plants use circulating pumps to keep things running smoothly. Whether it’s mixing chemicals, manufacturing products, or generating electricity, these pumps help control temperatures and keep equipment from overheating.

So, whether you’re staying warm in winter, keeping cool in summer, or simply turning on the tap, chances are, circulating pumps are quietly doing their job behind the scenes to make it all happen.

Choosing the Right Circulating Pump

When you’re picking out a circulating pump for a specific job, there are a few things you need to think about to make sure it works well and doesn’t waste energy:

How Much Fluid Do You Need to Move?

First, figure out how fast you need the fluid to move through the system. This depends on things like how wide the pipes are, how thick the fluid is, and how much pressure it needs to move against.

Can the Pump Handle the Pressure?

Check if the pump can handle the pressure in your system. This is important because it affects how well the pump can push the fluid through the pipes, especially if it’s going against gravity or dealing with friction.

Is It Energy-Efficient?

Look for a pump that’s energy efficient. This means it doesn’t use more energy than it needs to, which saves money and is better for the environment. Consider things like how efficient the motor is and if it has controls to adjust its speed.

Will It Last?

Make sure the pump is durable and reliable. You want it to be able to work well even in tough conditions and keep working for a long time without breaking down.

By carefully considering factors such as the flow rate, head pressure, material construction, and energy efficiency, you can select a circulating pump that is perfectly suited for the task at hand. This optimal choice not only ensures the smooth operation of your system but also leads to significant savings in both energy consumption and costs over time.

Trust JMI Mechanical

Circulating pumps are super important in many situations because they help move fluids around, control temperatures, and make systems work better. Basically, they keep things flowing smoothly. By knowing about the different kinds of circulating pumps, how they work, and what to think about when picking, installing, and taking care of them, people can make sure they get the most out of the technology without spending too much money or hurting the environment.

If you need top-notch maintenance and repairs in Indiana, JMI Mechanical is the team to call. Give us a ring today!

FREE QUOTE

Do you need help with HVAC or Plumbing service or maintenance? Fill out this form to get in touch with JMI Mechanical.

OFFICE LINE

ADDRESS

5610 Dividend Rd. Suite A, Indianapolis, IN 46241

WORKING HOURS

OPEN 24/7/365

OFFICE LINE

ADDRESS

5610 Dividend Rd Suite A, Indianapolis, IN 46241

WORKING HOURS